Products

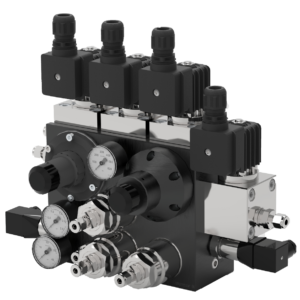

Bidirectional 2/2 Solenoid Valve

The solenoid valve block MV-H2-2/2 bidir-300/500 was designed as compact straight forward, economic flow control in and out of Hydrogen high pressure tanks up to working pressure of 300 / 500 barg.

The chemically nickel plated valve block is 100% corrosion resistant and optimized for the reliable management of Hydrogen storage and cascade refuelling systems etc.

An integrated certified REMBE® high pressure rupture disc (fail-safe performance, made in Germany) with negative temperature coefficient guarantees safety even in case of overpressure and fire.

An analog stainless steel pressure gauge allows a fast tool-free pressure check.

Swiss made

The chemically nickel plated valve block is 100% corrosion resistant and optimized for the reliable management of Hydrogen storage and cascade refuelling systems etc.

An integrated certified REMBE® high pressure rupture disc (fail-safe performance, made in Germany) with negative temperature coefficient guarantees safety even in case of overpressure and fire.

An analog stainless steel pressure gauge allows a fast tool-free pressure check.

Swiss made

Hydrogen Safety Cabinet

HomePower cabinet with extra «storm flooding tight gas room», prepared for forced air recirculation and outside blow up.

Suited for ®Enapter’s AEM EL 2.1/4.0 and peripheral units and other 19“ rack mounted Devices as Fuel Cells etc.

- space for integrated heat exchangers

- modular and scalable at your needs

- lower part reserved to peripherals without H2

- designed and produced in Switzerland

H2 Pressure Reduction, Gas Flow Control and Storage Management Block

Advanced hydrogen (H2) mono block for flow and pressure control.

- three pressure stages with high-quality 2-stage pressure reduction

- integrated solenoid valves (for electrically controlled flow regulation)

- pressure transmitter (for measuring and controlling pressure)

- G¼” connections with integrated microfilters

- high pressure side up to 500 bar

- precise pressure reduction for direct connection to the fuel cell inlet

- available with or without controlled outlet for vehicle refuelling (cascaded or direct)

- provides easy and safe integration of a H2 energy system with a minimum of pipe connections or possible leakage sources

- optimal in combination with the HomePower storage tank with bidirectional solenoid valve block

- designed and produced in Switzerland

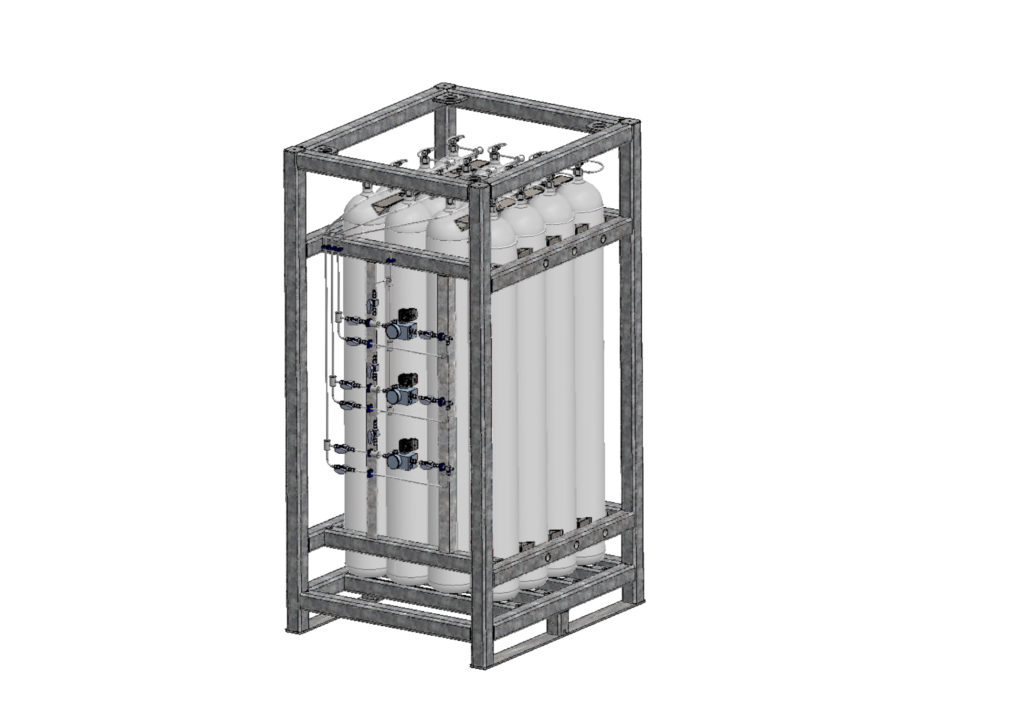

Hydrogen Storage Bundles

Type 1 H2 Storage Bundle:

- approved 50 l steel bottles from world top manufacturer

- best ecological and economic performance

- 100% recyclable, long durability (>=50 years), 500 barg and 300 barg operation pressure (20°C)

- includes bidirectional solenoid valve blocks to manage gas flow process

- PED and TPED standard available

- 1 to 3 independent segments/ pressure levels with corresponding valve blocks

- 1x16x50 l

- 2x 8×50 l

- 1x4x50 l + 1x12x50 l

- 2x4x50 l + 1x 8×50 l

Ready for cascaded H2 refueling of vehicles

Up to 25 kg H2 (500 barg, 20°C) respectively 825 kWh el./thermal energy

Enapter AEM Electrolyser EL 4.0

| Production rate | 500 NL/h, 1.0785 kg/24h |

| Output pressure | Up to 35 barg |

| Operative power consumption | 2.4 kW, beginning of life |

| Water consumption | ~ 400 mL/h |

| Ambient operative temperature range | 5 °C – 45 °C |

| Dimensions | W: 482 mm × D: 635 mm × H: 266 mm |

| Weight | 41 kg |

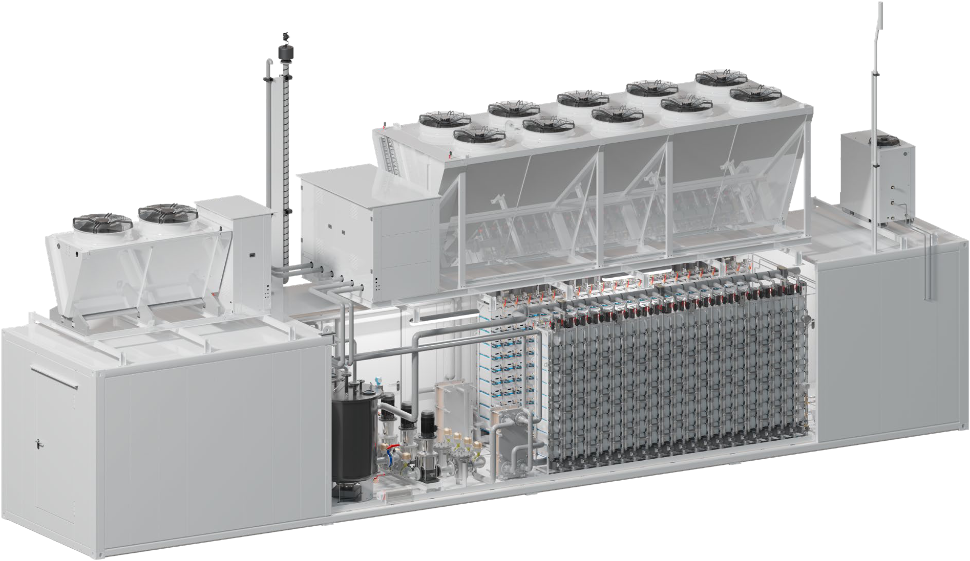

AEM Multicore

| Production rate | 210 Nm³/h, 450 kg/24 h |

| Output pressure |

Up to 35 barg |

| Operative power consumption | 1,008 kW, beginning of life |

| Water consumption | ~ 190 L/h |

| Ambient operative temperature range | -15 – 35 °C, up to 45 °C with hot-ambient version |

| Efficiency | max. 62.5% |

| Dimensions | L: 16 m × W: 3 m × H: 7.3 m |

| Weight | < 40 tons |

Indoor HydroCab

The high – quality 19” cabinet system from our Indoor HydroCab is particularly suitable for your individual indoor H2 application and includes up to five stackable electrolysers and one dryer.

| Cabinet outside dimensions | [W × D × H] 800 mm × 800 mm × 2200 mm |

| Available size inside | 42 U |

| Cabinet weight (empty) | 180 kg |